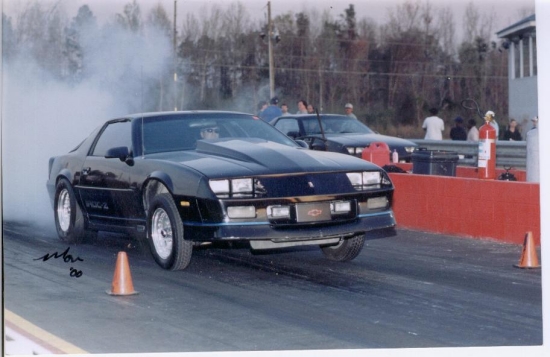

Alans 1988 Camaro IROC Z/28 "ZNX"

NEW ET 9.44 @ 146.7

Back in the day, when the 1988 Camaro IROC-Z28 was a stocker, it ran 15.70's with the base 5.7 TPI engine. With basic bolt on's, the car went 13.60's. Later a 150 shot NOS Nitrous kits was added. It sprung to an 11.90. Several years later, we built a 412 ci small block Chevrolet mil with aluminum heads, headers, Accel Super Ram box and cam kit. With the help of larger injectors, and FASTERPROMS.com, they help put the tune into a 12.19 @ 112 on motor alone.

One day my friend Andre bought an 1987 Buick Regal T-Type, with just basic bolt on's, and went a 12.05! With a few more bolt on's later, it ran the best of a 10.66 @ 127 and was still as streetable as my Camaro! I couldn't believe this little V6's performance, so I quickly bought a Grand National engine and put it in my Camaro.

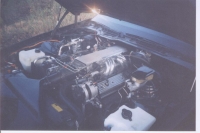

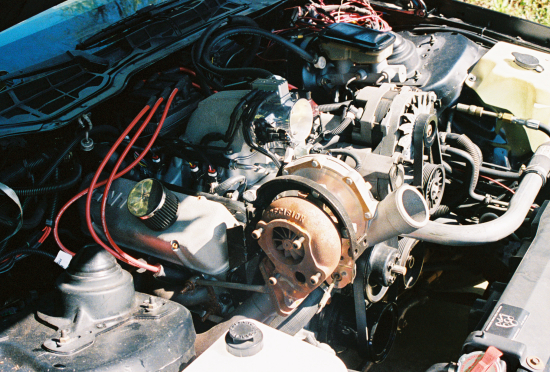

It all starts here. Under the Harwood Fiberglass 2 1/2" cowl hood, you will see that cold air is sucked through a 4" K&N Air Filter, a 3 1/2" Z06 LS1 MAF, and a 4" inlet pipe by a PTE 74 GTQ trim Turbo. Once the air is heated by the turbo, it must be cooled down by the PTE Front Mount Intercooler with 3" inlet / outlet piping. From there, it enters the A&A Performance prepped 109 block V6 mil through the 70mm Accufab throttle body and plenum. The Air is distributed through a Champion race ported stock intake manifold that is connected to a pair of Champion GN-1 Race ported aluminum heads. A Full Throttle Cam .224/.224 = .496/.496 flat tappet with Comp Cams push rods, push the T&D 1.65 Roller Rockers, which open the Manley stainless 1.90 / 1.60 valves that add just enough air to push down the TRW Forged standard bore pistons. The pistons are connected to a set of A&A Performance stock polished rods with ARP rod bolts. The stock crankshaft is held in place with the help of a RJC block girdle.

All of this air leaves the V6 by way of ATR Stainless headers and a PTE .85 exhaust housing. It exits through a 3 1/2"A&A Performance Custom stainless downpipe which is connected to a 4" Mufflex sewer pipe and a 4" two chamber Flowmaster muffler.

The fuel system consists of an A&A Performance custom in-tank dual pump set up. The two pumps are Walbro 340's. They send the fuel through the factory Camaro hard fuel lines to 6 PTE 75lb injectors.

The Ignition is pretty basic really, with a stock GN coil and modual, the MagnaCore wires send plenty of spark to the Autolite 3924 plugs.

The air and fuel is controlled by a Translator Plus+ and the stock 87 GN ECM, which has been modified by FULL THROTTLE and there Extender chip our chip burn was right on the money. We monitor all of the vitals with the help of Auto Meter gauges: Fuel, Boost, and Air / Fuel ratio. We also keep a sharp eye on what the computer is reading with a SCANMASTER 2. To make tweaks and finishing touchs, our Direct Scan and laptop helps us out along the way.

The Power the V6 makes is sent from the JW flywheel to the GER 3800 non-lockup converter. A TRANSKING TH400 with a reverse manual valve body and transbrake holds up nicely while building outrageous boost on the starting line. A Heavy Duty custom built 3 1/2" driveshaft sends the monster torque to the "living on borrowed time" Factory IROC-Z Borg-Warner 9 bolt rear end with 3.27 gear ratio. Sticking the power to the pavement are a simple set of 26 x 10.5 x 16 Mickey Thompson ET Streets mounted on stock GM 16x8 GNX style "Super lite" wheels. The suspension is basicly stock with boxed lower contol arms and Energy Suspension bushings. We did however add a S&W Adjustable torque Arm for hard launches and correcting the pinion angle.

The Camaro's Race weight is 3240lbs with 1/2 tank of 118 octane VIP Race fuel

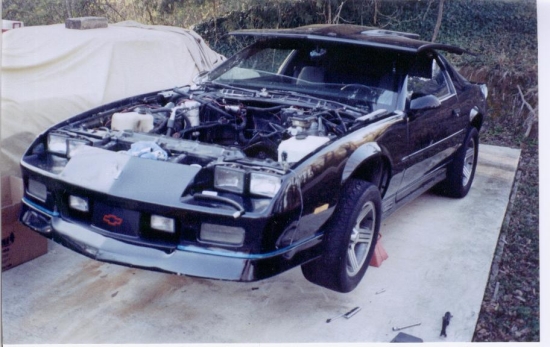

The latest build up is a Buick LC2 3.8L SFI turbo intercooled V6 from a 1987 Buick Grand National. A hybrid was always a thought with the Camaro, so what better way to build a sleeper than with less weight from the engine bay, and less noise from the exhaust tips. This is insider tips on the build up and what it took to make this project come to life.

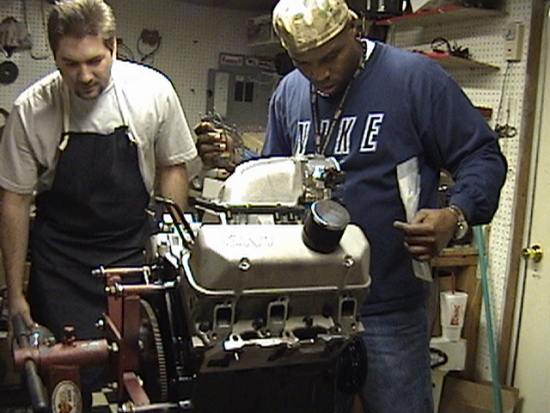

Alan and Andre building the Buick 3.8

Test fitting the V6 in the Camaro engine bay, revield that we can use the frame and engine mounts from the 87 Grand National in the Camaro, instead of the discontinued TTA engine mounts. We had to add 3/8" thick steel plate to the bottom of the frame mount, only because the 1" thick block girdle moved the V6 oil pan into the Camaro crossmember.

The passenger side unibody rail had to be notched to clean the ATR crossover pipe clamp.

Header clearance after the notch was perfect. I bought heater box for an A/C delete Camaro because with GN-1 Aluminum heads, you loose A/C

The PTE Front mount intercooler is custom mounted using 2 pieces of 1" x 1"x 6" aluminum brackets. The transmission and oil coolers can be seen mounted behind the intercooler.

The Camaro grill, fog lights, and support braces were removed for maximum air flow to the intercooler.

We chose to run the intercooler piping up over the radiator for several reasons. It shortened the length of piping, no ground clearance problems, and no heat soak being away from the radiator. Only drawback was we lost the hood latch and had to settle for hood pins.

Once the engine was set in place, everything bolted and came together like it should.

With the new intercooler piping in place, there were no hood clearance problems. But we did loose the hood latch.

Now some engine pics of the turbo camaro.

FAST FORWARD Motorsports in Arkansas really out did themselves with the flawless fabrication seen here. Check out the 4 inch inlet, 3 1/2 inch down pipe, and 3 inch intercooler piping. CASPERS ELECTRONICS made our wiring harness for the LC2 to work in the Camaro as well.

With everything in place we went straight to the track. First pass off the trailer netted a 12.00 @ 117mph. Turns out we were blowing though the converter. So we put in a new 3600 converter in and we got the ET we were looking for! 10.83 @ 134mph on 26psi, leaving the line on O boost. After the car crossed the line at 134mph, I found out I didnt have enough brakes to stop that mph and into the sand pit I went!! The next upgrade was BRAKES!!

I found a friend that was parting out a 1989 Turbo TA and was able to swap my 10" front brakes and the stock 9 bolt rearend for his 1LE 11.5 front brakes and a Moser Ford 9" with F150 rear brakes. I added a Strange center with 3.50 gears and Detroit locker, now I can leave hard on boost and stop quicker.

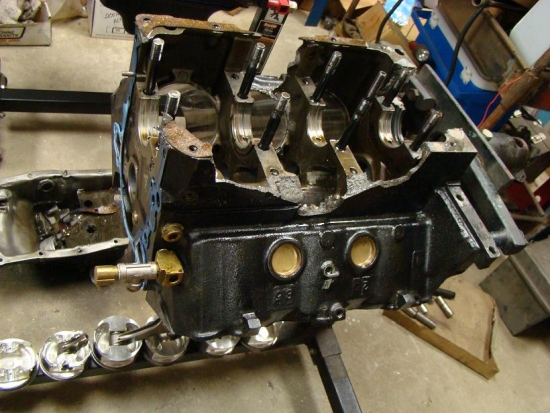

After a few short months, it was time to build the stage motor. So we picked up a 4.1 stage block from Lee Thompson of Indiana and started the new project. This build had the flowing, BA 3.625 steel crank, K1 H beam rods, and J&E pistons. The cam was a Comp Cams 236/236 solid roller and the heads were TA Street Eleminators. Since it was a stage block, I thought a new Champion intake would be just right. I ordered a new FAST XFI from Cal Hartline of Hartline Performance and he sent it with a very nice start up program. With all this new hp the stock GM 7004R tranny could not hold up, so it was replaced with a TH400 with a transbrake and 3800 converter. It has been a long learning process with a few $$$ mishaps, lots of sparkplugs and headgaskets! We have added the EGT probes to allow us to monitor and correct each cylinder individually really helps and is an absolute MUST in tuning these engines.

The current engine in the car now is the original test mule we learned on. It's a 231cid 109 block with heavily ported stock iron heads and smaller Comp Cam 224/224 solid roller with Scorpion hyd. roller lifters, which gave me back the oil psi that I lost going with the solid lifters. The new lifters caused the engine to idle so smooth, you cant tell its running. The current ET with this combo is 10.40 @ 136mph on a conservative tune with only 19 psi vs 25 psi. Plus its now 500lbs heavier due to the new TH400 tranny, Ford 9", 3.5" steel drive shaft, heavy Harwood fiberglass hood, and custom roll cage.

I cant wait to put the stage motor back in and turn up the boost!

Another little strocker going in the turbo camaro.

This is called windowing the block, due to a bad fuel pump wiring harness.

Trying out a new little stroker.

Well good results a 9.44 @ 146.7

We ran such a good number with that little stroker, that I sold it to Brian and he has been driving it to work once a week about 50 miles one way and getting 19 mpg too, not to bad for a V6 putting 800 hp to the tires!!

We started another little stroker from scratch, trying some new things like race ported heads, not the box stock heads like on the last one and a new double ball bearing billet 71mm turbo with a 4 bolt exhaust housing that flows more than the stock style 3 bolt. We also dropped some weight off the nose, about 115lbs! We removed the power streeing (40lbs)and installed a manual steering box from a Chevy S-10 pick up, (20lbs) along with tubular lower control arms, coil overs and a Wilwood disc brake set up from Bruce @ Hawks Third Gen.org. He talked me into the "street set-up" because he knew I still street drive my car alot, and I am glad he did! It has good street manners but It will have to go back to Randy @ Fast Forward in Arkansas to have a new custom down pipe made and some other things that need to be tweaked a bit. So when it returns, we can start tuning in the little monster, maybe we can get that 8 second pass and still be just as streetable as ever.

Special Thanks to: My loving and beautiful wife, Debbie, for making this possible and for putting up with all the headaches and late night hours put into this project. Andre Ellis, Jason Cheney, Brian Dykes Randy Alexander, Mike McKay at Performance Machine, Randy at FAST Forward Motorsports, Lee Thompson, Troy at TroyBuilt Transmissions. (No, we dont have a Troybuilt Tiller transmission in the car!) and Cal Hartline, Otto for the FastFXI tuning help. And everyone at www.turbobuick.com for thier input suggestions.

Always up dating and changing!